asme hardness testing|astm e18 latest revision : discount store 1.3 The portable hardness testers covered by this test method are verified only by the indirect verification method. Although the portable hardness testers are designed to employ the same test conditions as those defined in the standard test methods, the forces applied by the portable Rockwell and Brinell testers and the depth measuring systems of the portable .

Resultado da Elche Feminino. Levante II Feminino. 2 - 1. SÁB, 13/01. Resultado do último jogo Elche Feminino, placar dos últimos jogos, resultado do jogo de ontem Elche Feminino. Quanto foi o jogo Elche Feminino?

{plog:ftitle_list}

webLágrima de Amor. Beto Guedes. eu te amo. por toda terra e todo azul. não entendo. a violência em que vais. só na minha cama. eu vejo aquela estrela que nos chama. deixo .

Only QW-290 for temper bead welding defines hardness testing. Hardness testing of carbon steels are not defined in most construction Codes; it is addressed in API-582 and various NACE publications as a means to mitigate stress corrosion cracking. ASME Codes place the . Listed below are common American Society for Testing and Materials (ASTM) .

Metallographic and Materialographic Specimen Preparation, Light Microscopy, Image Analysis and Hardness Testing. 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959: ASTM International, 2007.

The Vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – .Abstract. The standard superficial Rockwell 15Y hardness test has been adapted for use on concrete. Hardness measurements were made on the mortar regions between the coarse aggregate pieces. A correlation between this hardness and the concrete's compressive strength was developed. For 7.5- by 15-cm (3- by 6-in.) cylinders, it is Rockwell 15Y hardness = 73.5 .

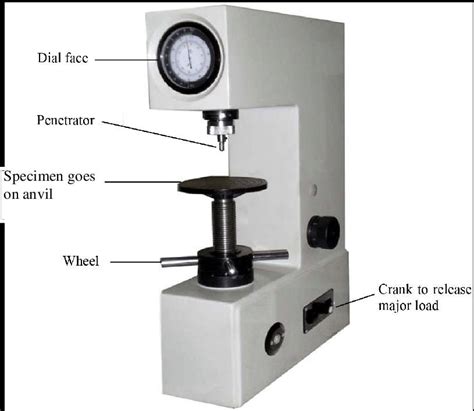

1.3 The portable hardness testers covered by this test method are verified only by the indirect verification method. Although the portable hardness testers are designed to employ the same test conditions as those defined in the standard test methods, the forces applied by the portable Rockwell and Brinell testers and the depth measuring systems of the portable .Rockwell hardness test is one of the static hardness testing methods using indentation depth as a measuring criterion. Basically, two types of indenter are used; one Diamond O spheroconical (Brale) indenter with an angle of 120 and a spherical tip of 0.2mm; second is steel ball indenter with diameters as 1/16, 1/8, 1/4, ½ inches.

rockwell hardness testing procedure pdf

The Rockwell and Brinell hardness tests are performed using a hardness tester (United Testing Systems, True-Blue Universal), according to ASTM E18 [] and E10 [], respectively.A carbide indenter ball with a diameter of 1.59 mm is employed to make an indentation on the surface of a sample.

AND TEST PROCEDURE FOR LEEB HARDNESS TEST 6. Apparatus 6.1 The instrument used for Leeb hardness testing consists of (1) an impact device that is equipped with a spherically shaped tungsten carbide, silicon nitride, or synthetic diamond tipped impact body, an induction coil velocity measuring assembly, and a support ring, and (2) an electronic .This document extensively references American Society for Testing and Materials (ASTM) Standard Methods and spec-ifies how to use these methods when testing weldments. It takes into consideration the variations in properties that can . hardness testing and stud weld tests, and organized the tests by weld type. The sixth edition (1998) added .

3.1.4 Brinell hardness test—an indentation hardness test using a verified machine to force an indenter (tungsten carbide ball with . 1 This test method is under the jurisdiction of ASTM Committee E28 on Mechanical Testing and is the direct responsibility of Subcommittee E28.06 on Indentation Hardness Testing. Current edition approved Jan .

ASTM E18 is the industry standard for Rockwell hardness testing of metallic materials. This specification includes both theory and standard practice statements. For those companies Nadcap accredited in heat treat where the AC7102/5 for hardness and conductivity testing is included, an additional layer of requirements come into play.

rockwell hardness testing guide pdf

The Brinell hardness HBW results from the quotient of the applied test force F (in newtons N) and the surface area of the residual indentation on the specimen (the projection of the indentation) after removal of the test force (see Brinell formula).To calculate the surface area of the residual ball indentation, the arithmetic mean d of the two perpendicular diagonals d1 and d2 (in mm) is .

Standard Test Method for Leeb Hardness Testing of Steel Products A0956_A0956M-22 ASTM|A0956_A0956M-22|en-US Standard Test Method for Leeb Hardness Testing of Steel Products Standard A956/A956M Standard Test Method for Leeb Hardness Testing of Steel Products> new BOS Vol. 01.03 Committee A01 $ 76.00 In stock Abstract. We determined the effect of the core sample dimensions on the measured values of the Schmidt rebound hardness and proposed a way to correct it to obtain unaffected value. The effect was previously investigated on cubes, where a clear dependence of the rebound hardness on the cube edge was proved. For cylindrical bodies, however, the problem is more .

ASTM's physical and mechanical testing standards provide guides for the proper procedures employed in the determination of the physical, mechanical, and metallographic properties of certain materials, particularly metals and alloys. . Indentation Hardness Testing. E140-12B(2019)e1 Standard Hardness Conversion Tables for Metals Relationship . Read the applicable ASTM standards and contact a Paulo metallurgist to discuss hardness testing methods. Our commitment to educating customers has been a key to our success over 75 years in business , and .

ASTM E10 defines the Brinell hardness test as an indentation hardness test performed in a verified machine by forcing a tungsten carbide indenter into the test material surface. 2. Brinell Hardness Test Procedure. The Brinell . Abstract. Polymer durometry is the measurement of the hardness of plastic and rubber materials using an indentor. Many different hardness scales and indentor geometries have been standardized for durometry. Indentation into a solid is governed by linear elastic mechanics, and this paper relates the Young’s modulus to standardized hardness scale reading. We .

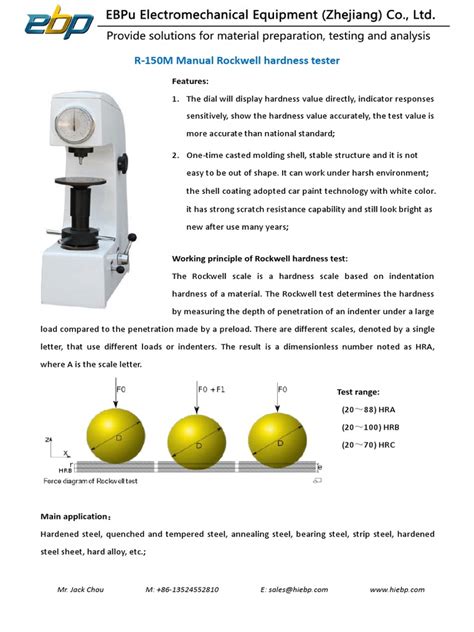

For many years, ASTM E384, Standard Test Method for Microindentation Hardness of Materials, has stated that the load range for microindentation hardness testing with both Knoop and Vickers indenters is 1 gf to 1,000 gf.But, is it realistic to consider using very low-test forces when the indents are measured with a light optical microscope? Abstract. This book was written with the aim of increasing the awareness of materials scientists, metallurgists, and engineers of recent developments in hardness testing of modern ceramics. Hardness is not a unique property, but is a response of the material to a specific indentor and test conditions. Several models of hardness are presented including . Abstract. Mechanical hardness testing is fundamental in the evaluation of the mechanical properties of metallic materials due to the fact that the hardness values allow one to determine the wear resistance of the material involved, as well as the approximate values of its ductility and flow tension, among a number of other key characteristics. As a result, the main .test: the Rockwell hardness test and the Rockwell superficial hardness test. The significant difference between the two test classifications is in the test forces that are used. For the Rockwell hardness test, the preliminary test force is 10 kgf (98 N) and the total test forces are 60 kgf (589 N), 100 kgf (981 N), and 150 kgf (1471 N).

astm standards for hardness testing

Abstract. Vickers hardness indentations on a steel gage block (-900 HV) with diagonals between 3.4 and 44 µm have been measured with a calibrated atomic force microscope (AFM) and with an opticalbased method. From the AFM images the diagonals were measured from hard copies of diagonal profiles and automatically by image analysis. The combined .Method A is based on the increase in tensile stress during load application. In the linear elastic part of the tensile test, that is at the very beginning of the test, the rate of stress application must be between 1.15 and 11.5 MPa/sec (this corresponds to 10000 and 100000 psi/min).; However, it is clearly stated in ASTM E8 and ASTM E8M that these specifications and method do not .

Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .%PDF-1.5 %¡³Å× 1 0 obj >/ProcSet[/PDF/Text]>>/Type/XObject/BBox[ 0 0 595 839]/Length 20/Matrix[ 1 0 0 1 0 0]/Filter/FlateDecode>>stream xœ3T0BC0™œ«P¨ ò d .Section IX ASME BPVC paragraph QW-290.5 (c) & figure QW-462.12 for temper bead techniques, testing may use HV5, and instrumented indentation testing shall not be . At least one hardness test shall be performed for each Hardness greater than limit may be accepted when unique welding process/filler metal heat numberappendixes which relates to the Rockwell hardness test. List of ASTM Standards Giving Hardness Values Corre-sponding to Tensile Strength Appendix X1 Examples of Procedures for Determining Rockwell Hardness Uncertainty Appendix X2 1.4 Units—At the time the Rockwell hardness test was developed, the force levels were specified in units of

java.lang.securityexception unknown calling package name test

java unit test package structure

English - Metin2 - Gameforge

asme hardness testing|astm e18 latest revision